Variable valve timing has made a big revolution in internal combustion engines. The technology had gained huge popularity in the 1990s, but what are the differences between the three most popular systems?

Internal combustion engines were not as effective in the past. They had about 33% thermal efficiency, and the remaining energy created by combustion of the air-fuel mixture is separated into the environment. They began to look for any ways to construct a more efficient internal combustion engine and variable valve timing turned out to be the most effective solution for that.

Through it changes the timing (the point at which the valve opens and closes during the engine cycle), the time during which the valve remains open, and the degree of the valve lift.

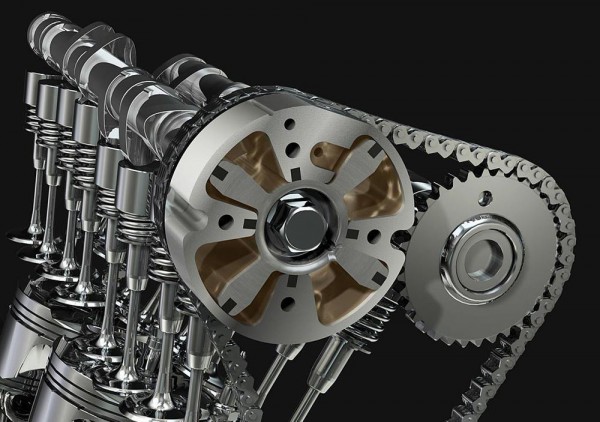

As you know, the inlet valve opens to allow the entry of air / fuel mixture into the cylinder, which is then compressed, burnt and thrown out through the exhaust valve. These valves regulate thanks to the rocker transmitting pressure from the camshaft for their perfect opening and closing.

Unfortunately, the standard camshafts are designed in a way that allows a constant setting for the opening and closing of the valves. This is a problem because for maximum effectiveness the valves should be opened and closed in different ways to the engine speed.

At high engine speeds you would like a little quicker opening of the intake valve, because otherwise the cylinder may suffer from shortness of breath. Therefore, regulation of the opening of the intake valve allows the entrance of more oxygen in the cylinder and thus enhanced engine efficiency.

It happens that instead of reaching a compromise between the camshaft at low or high speeds, variable valve timing leads to efficiency in both scenarios. There are several different approaches to this technology. The most famous are the following:

..CLICK BELOW ON NEXT PAGE to CONTINUE and Read more about the VTEC technology…

- 1

- 2

- 3

- 4

- Next page »

Comments